Objective

This blog provides an explanation of the intumescent coating’s functions and why they are important in modern-day structures, and how they can help with long-term fire safety as well as compliance.

Our aim is to assist facility managers, building owners and project teams in comprehending the options for passive fire protection in a way that is clear and confident.

Key Takeaways

- What intumescent coatings are and how they respond to fire

- Why steel and load-bearing elements need passive protection

- How these systems support safety, compliance, and continuity

- Where intumescent coatings deliver the most value

Introduction

Fire rarely gives warnings, but the right protection buys time. That idea sits at the heart of modern building safety.

Today’s buildings are larger, busier, and held to stricter fire rules than ever before. When a fire breaks out, people need time to get out, and structures need time to stay standing.

That’s exactly where fire-resistant paint UK, proves its value, especially in buildings supported by steel frames.

UK fire safety guidance recognises passive fire protection as a trusted way to slow structural failure, with testing showing steel can be protected for up to two hours under extreme heat.

What Are Intumescent Coatings and Why They Matter

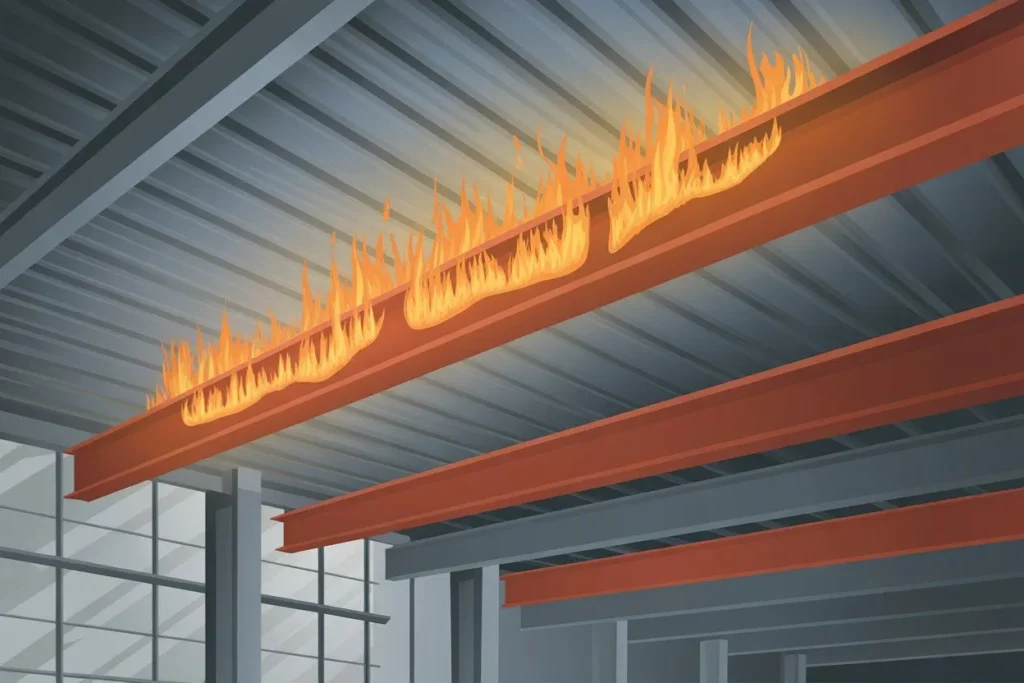

Intumescent coatings are fire-proof paints applied to structural parts, usually steel. Under normal conditions, they look like a standard decorative finish. When exposed to high heat, they react in a very specific way that protects the structure beneath.

Unlike active systems that require water, power, or manually input, intumescent coatings remain in operation. They remain in the background, waiting to react when temperatures increase.

This makes them a core part of modern commercial fire protection strategies, especially in buildings where uninterrupted protection is critical.

How Intumescent Coatings Support Modern Fire Protection Strategies

Fire protection today is about layers. Alarms alert people. Sprinklers slow flames. Passive systems protect the structure itself. Intumescent coatings sit firmly in that last category.

Passive fire safety and structural resilience

Passive structural fire safety works without switches, sensors, or human action. When fire heats the coating, it expands many times its original thickness and forms a char layer. This layer reduces heat transfer into the lower steel.

What is the significance of this? Steel loses its strength rapidly when heated. It is helpful to delay the temperature rise:

- Keep escape routes stable

- Help prevent early collapse

- Support safe firefighting operations

Fire resistance periods, such as 30, 60, or 120 minutes, directly relate to how long a structure can safely stand during a fire. Intumescent systems are designed to meet those ratings.

What Happens When Intumescent Coatings Are Exposed to Fire

These coatings are designed to react, not resist passively.

Fire-resistant paint UK performance explained.

When exposed to fire, the coating swells and forms a thick insulating char. This char:

- Acts as a heat barrier

- Reduces oxygen reaching the steel

- Slows temperature rise

This is why fire-resistant paint UK systems are so widely specified for structural steel in regulated buildings.

Steel structure fire coating under extreme heat

Steel can lose up to half its strength at around 550°C. A steel structure’s fire coating delays reaching that point. By keeping the steel cooler for longer, the coating helps the frame hold its load during evacuation.

The result is improved building stability and reduced risk of sudden collapse.

Why Passive Protection Is Essential for Commercial Buildings

Commercial properties face higher occupancy levels and stricter legal duties. Relying only on alarms or suppression systems leaves a gap.

Passive structural fire safety in real environments

Intumescent systems are used in:

- Offices and business parks

- Hospitals and care facilities

- Schools and universities

- Residential apartment blocks

Because they sit directly on the structure, they offer hidden protection that doesn’t change the look or layout of a space. They also work well alongside architectural finishes, which is important in visible areas.

This method improves security for commercial fire protection while not affecting the design of buildings.

Key Benefits That Go Beyond Fire Resistance

Fire safety is a matter of important business decisions. Intumescent systems can be beneficial long after the installation.

Intumescent paint benefits for long-term asset protection

Some key advantages include:

- Clean appearance that blends with design finishes

- Easier upgrades during refurbishments

- Reduced need for bulky fire boards

- Support for insurance risk assessments

These intumescent paint benefits make coatings a practical choice for both new builds and upgrades.

Intumescent coatings, fire protection, and compliance confidence

Fire ratings are backed by tested systems and clear certification. When installed correctly, coatings help buildings meet UK regulations and inspection standards.

Ongoing checks focus on coating condition and thickness, not daily operation. That simplicity adds confidence for duty holders.

Professional Application and Why It Matters

Even the best system fails if it’s applied incorrectly.

Fire-resistant paint UK standards and testing

Application quality depends on:

- Correct surface preparation

- Accurate dry film thickness

- Controlled application methods

- Clear site records

Accredited installers follow strict processes to make sure the coating performs as tested. This is where experienced specialists like CA Fire Protection add real value, especially on live sites.

Real-World Applications Across UK Commercial Buildings

From offices to hospitals, intumescent systems protect structures every day without being noticed.

Steel structure fire coating in live environments

We often see coatings used during refurbishments where steel frames are already in place. The coating allows upgrades without major structural changes.

On new developments, intumescent systems are planned early, making them easier to apply and inspect.

“Passive protection remains vital because it buys time when everything else is under pressure,” notes one UK fire safety consultant. “It supports every other system in the building.”

Choosing the Right System for Your Building

No two buildings are the same. Fire protection must reflect how a space is used.

Intumescent paint benefits versus alternative methods

Compared with boards or cladding, coatings:

- Take up less space

- Follow complex steel shapes

- Often reduces installation time

Boards may suit some areas, but coatings are often preferred where space, access, or appearance matter.

Build Safer, Smarter, and With Confidence

Fire protection should never be an afterthought. When chosen and applied correctly, intumescent systems quietly protect lives, assets, and operations every day. For organisations focused on safe, compliant buildings, understanding how these coatings work is a vital step forward.

CTA: Count on CA Fire Protection to provide professional guidance and results throughout specification development, application, and compliance. Contact us today and be in control of your building’s fire safety in confidence.

Frequenty Asked Questions

How long do intumescent coatings last once applied?

When installed and maintained correctly, they can last for decades with routine inspections.

Are intumescent coatings suitable for existing buildings?

Yes. They are commonly used in refurbishments to improve fire resistance without major disruption.

Do intumescent coatings replace fire alarms or sprinklers?

No. They work alongside active systems by protecting the structure itself.

How is fire resistance measured for intumescent coatings?

Through controlled furnace testing that confirms time-based fire ratings.

Who is responsible for maintaining passive fire protection?

Building owners and duty holders are responsible for inspection and upkeep.